What is 5S and Why is it Important?

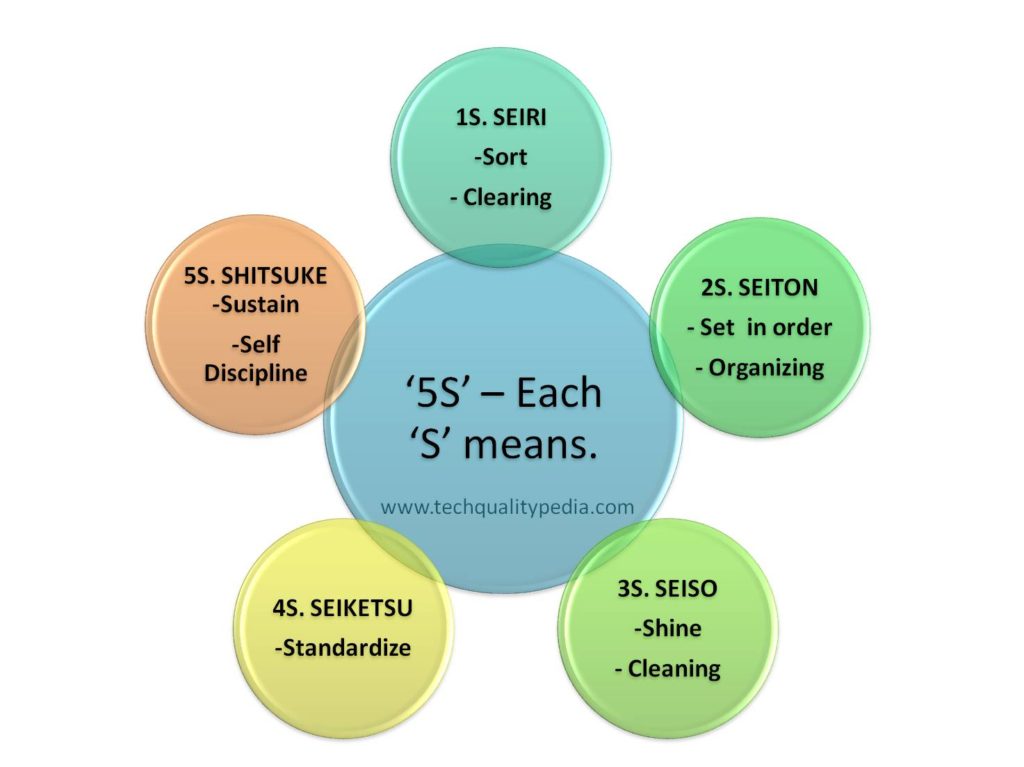

on December 2, 2022 Sort is the first, and most important step in the 5S methodology. Sort relates to tidiness and the absence of clutter. Here is a deeper dive into the distinction: WHAT DOES SORT MEAN IN THE 5S METHODOLOGY? Sort is derived from the Japanese word Seiri (整理).

5S — The Basics of Workplace Organization Better MRO

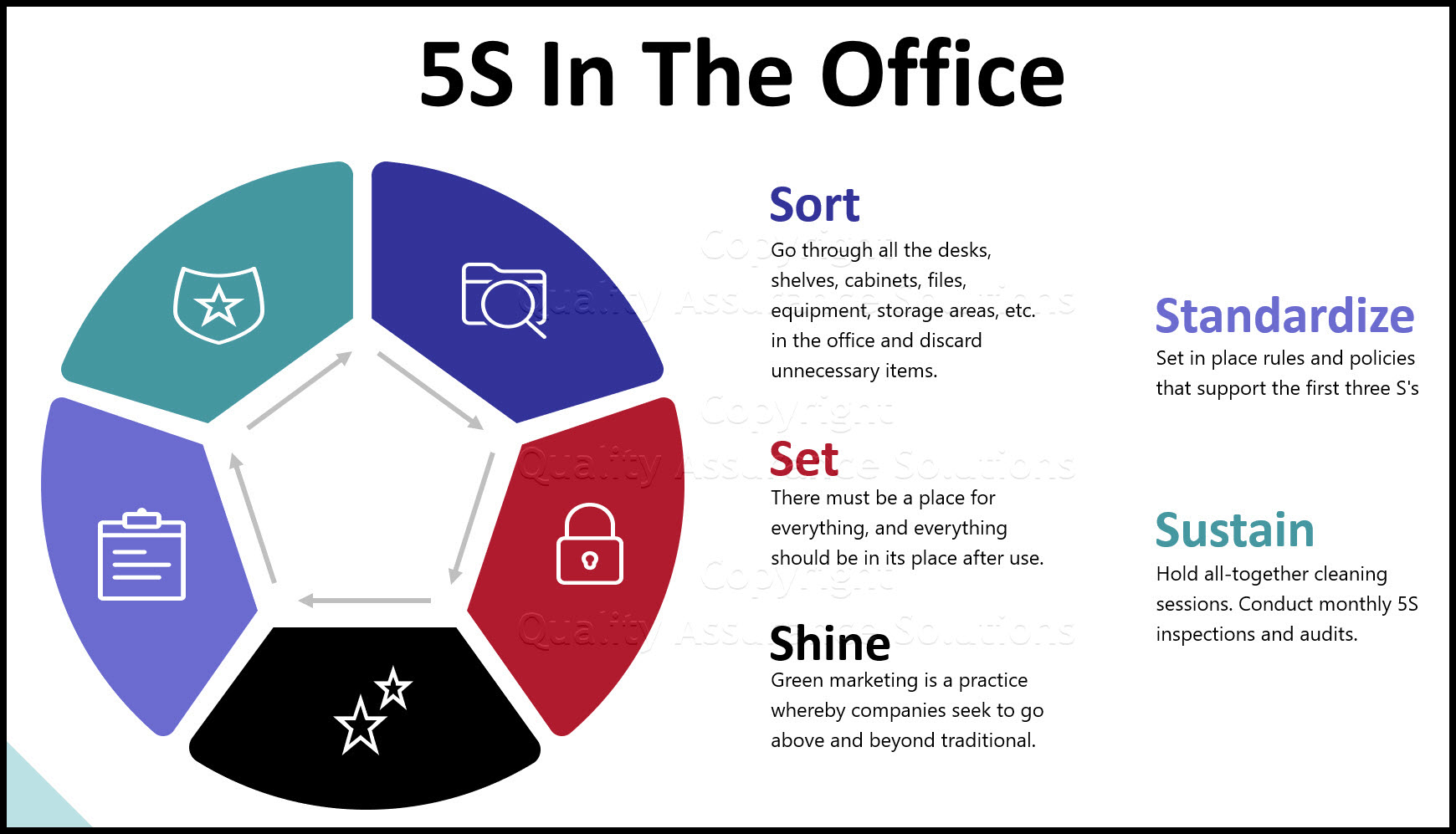

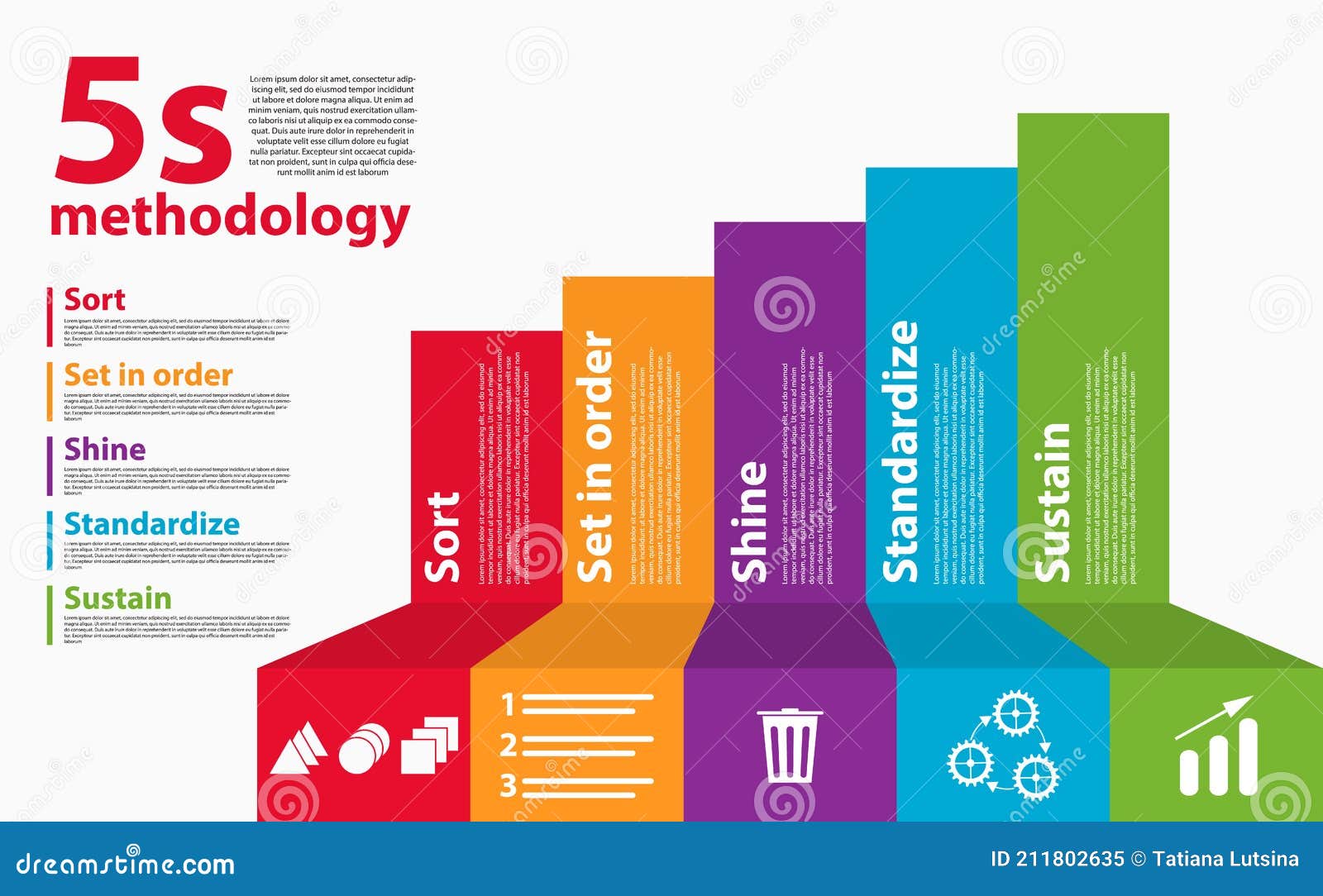

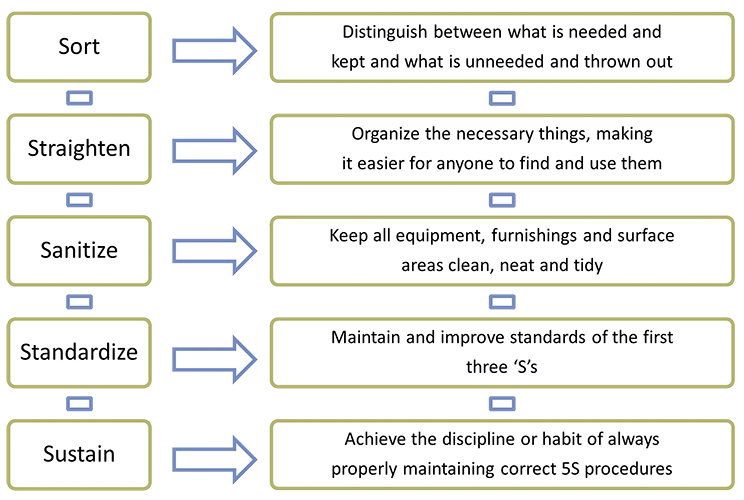

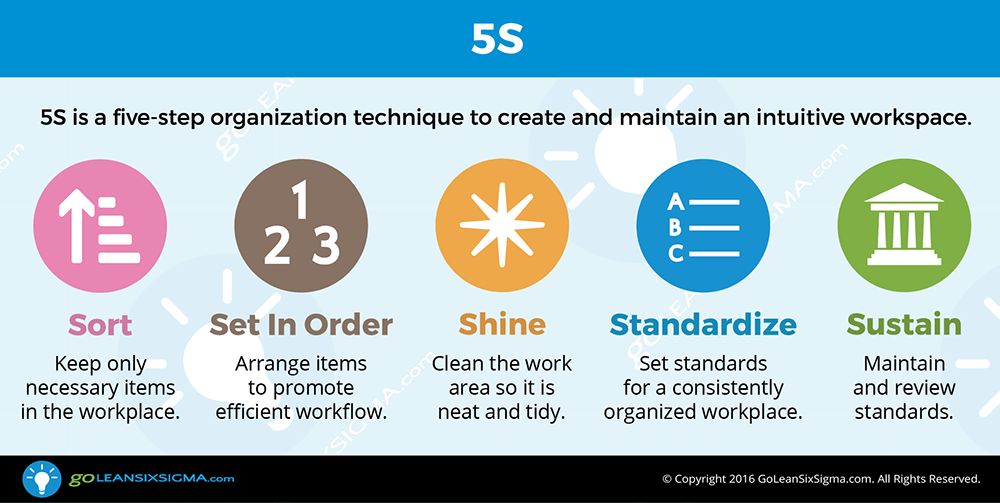

The "5" refers to five Japanese words that begin with the letter "S" when translated into English. There are many definitions (some available in great depth); below is a basic, layman's description for each step. • Sort: Determine what is appropriate or necessary, and discard everything that is not.

5S Program Sort Creative Safety Supply Blog

Seiri Seiton Seisou Seiketsu Shitsuke 5S Meaning in English In English, these 5S meanings are: Sort (Seiri): Eliminate that which is not needed. Straighten (Seiton): Organize what remains after sorting. Shine (Seisou): Clean and inspect the work area. Standardize (Seiketsu): Write standards for 5S.

5s Standardize Examples

Resource Center Lean Manufacturing & Safety Glossary 5S - Sort.

5S Methodology Management Chart Diagram with Sort. Set in Order. Shine. Standardize and Sustain

Methodology Six Sigma Getting Organized With 5S: Sort, Set, Shine, Standardize, Sustain The philosophy of 5S represents a way of focusing and thinking in order to better organize and manage workspace, specifically by eliminating the 8 wastes as defined by the Lean Manufacturing system.

5S Methodology

Sort (seiri 整理) [ edit] 1S - a red tag area containing items waiting for removal. Seiri is sorting through all items in a location and removing all unnecessary items from the location. Goals: Reduce time loss looking for an item by reducing the number of unnecessary items. Reduce the chance of distraction by unnecessary items. Simplify inspection.

The Steps of 5S

Sort : Separate out all that is unneeded and eliminate it. 2. Straighten (Set) : Put things in order, everything has a place. 3. Scrub ( or shine) : Clean everything, make the workplace spotless. 4. Standardize : Make cleaning and checking routine. 5. Sustain : Sustain the previous 4 steps and improve continually on them.

The Workplace Organization 5S Methodology Sort, Set in Order, Shine, Standardize and Sustain. 5S

What is 5S? 5S is a system for organizing spaces so work can.

1st S of 5S Methodology Seiri or Sort Working area, Hand lettering for beginners, Sorting

Quality Resources / Lean / Five S Tutorial What are the Five S's (5S) of Lean Quality Glossary Definition: Five S's (5S) 5S is defined as a methodology that results in a workplace that is clean, uncluttered, safe, and well organized to help reduce waste and optimize productivity.

5S full form 5S Meaning 5S System Implementation steps with Benefits

5s is a philosophy applied in the workplace that helps promote efficiency and effectiveness. As one of the core principles of kaizen, 5S lean principles can help identify and eliminate wastage to achieve a well organized and safe working environment.

What Is 5S A Lean Methodology Flow Consulting

A 5S map is a diagram or floor plan that provides an overview of a work area, process, or station. It provides a visual reference to show where the tools, supplies, workers, and travel paths are, and how they relate to each other. A good map may also include a description of the work that happens in the area shown.

Applying 5S in the Manufacturing Industry Lean Production

The goal of the first of the 5S's, Sort, is to have only what is needed for the job in the work area.. The Sort phase applies to all work areas, manufacturing departments, service processes, and offices. A Resource Engineering Company. PO Box 449, Waitsfield, VT 05673 USA. 800-810-8326 (Toll-Free) 802-496-5888 (Outside of N. America)

5S System for Cleaning and Organizing Kaufman Global operational excellence

5S is the name of a workplace organization method that uses a list of five words: in English (Japanise) Sort (Seiri), The goal of Sort is to eliminate all the unneeded tools and materials and create an organized space free of clutter.

5S Infographics A Brief & More Detailed Overview

Stage one is referred to as SORTING. At this stage, an evaluation of the need for everything that can currently be found in the work area is conducted. For every part, material, or tool in the area, you can ask the question: is this tool/material necessary to perform the task?

5S Methodology

What does Sort mean in the 5S methodology? Sort is derived from the Japanese word Seiri (整理). All materials, including equipment, tools and supplies, and work-related objects, should be examined in this process. Sort is the word used to define the step where unnecessary objects are removed.

What is 5S ? 5S System is explained including tips on getting a 5S program started.

Sort, one of the 5S (sort, straighten, shine, standardize, sustain) activities, helps teams reinvent work areas by deciding which items are required for daily activities and relocating those items that are infrequently needed or not used in the work area.