3 M's Muda, Mura, Muri Lean Poster, 16" X 20", Made in The USA Amazon

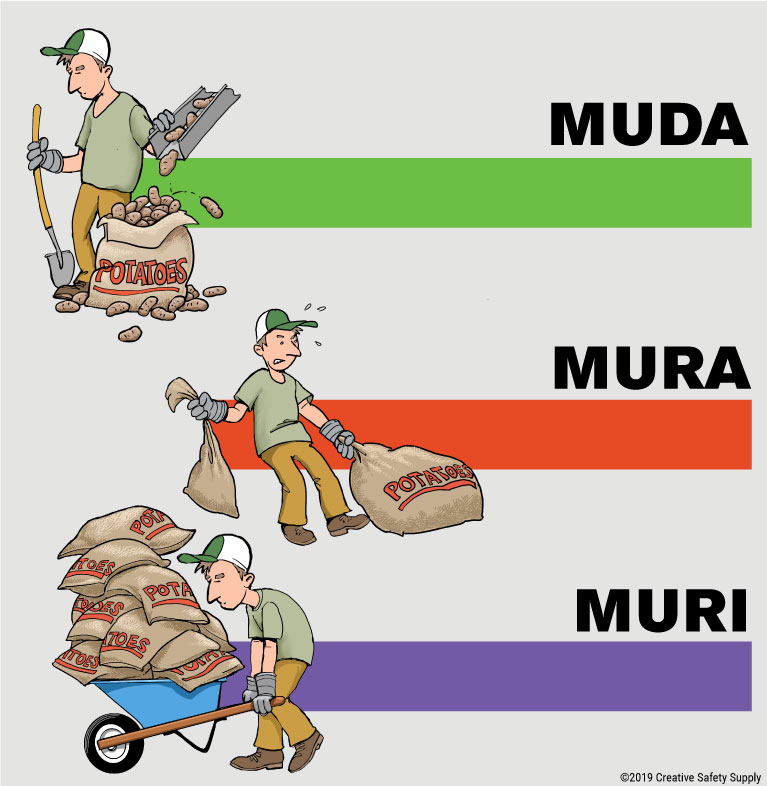

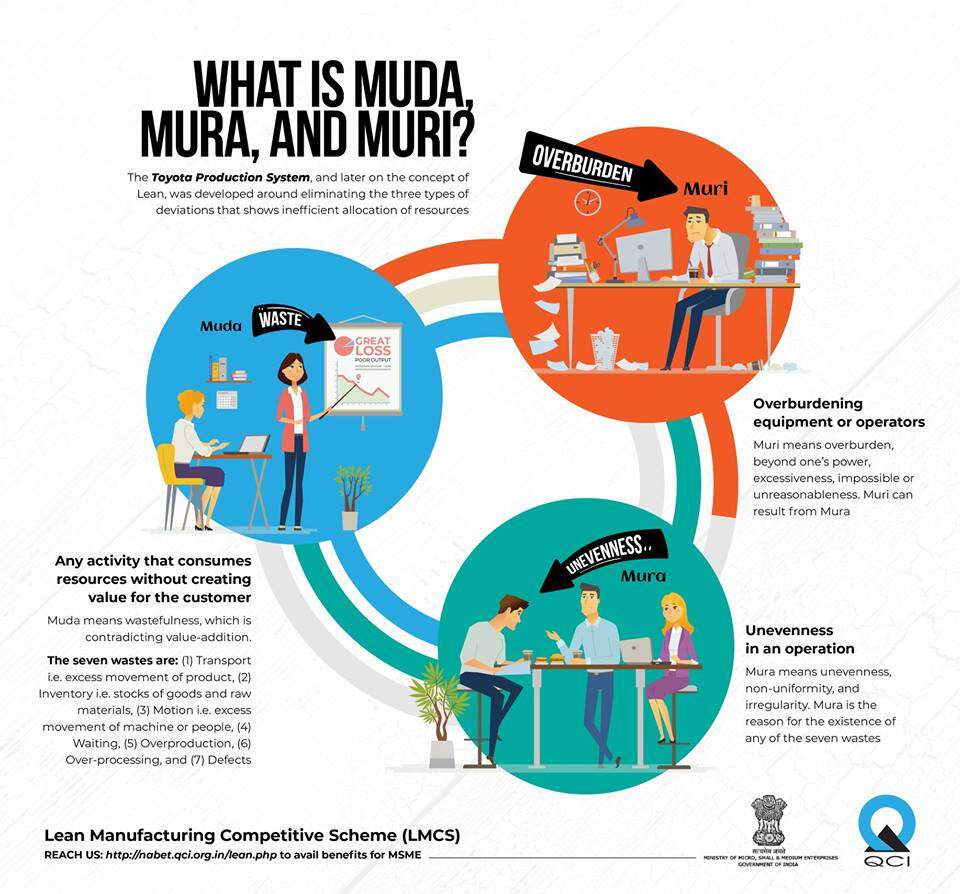

Muda, Mura, and Muri are terms often used together in the Toyota Production System (and called the Three Ms) that collectively describe wasteful practices to be eliminated. An Introduction to Muda, Mura, and Muri Watch on Muda Any activity that consumes resources without creating value for the customer.

Muda, mura y muri ¿Cómo identificarlos y reducirlos? EON

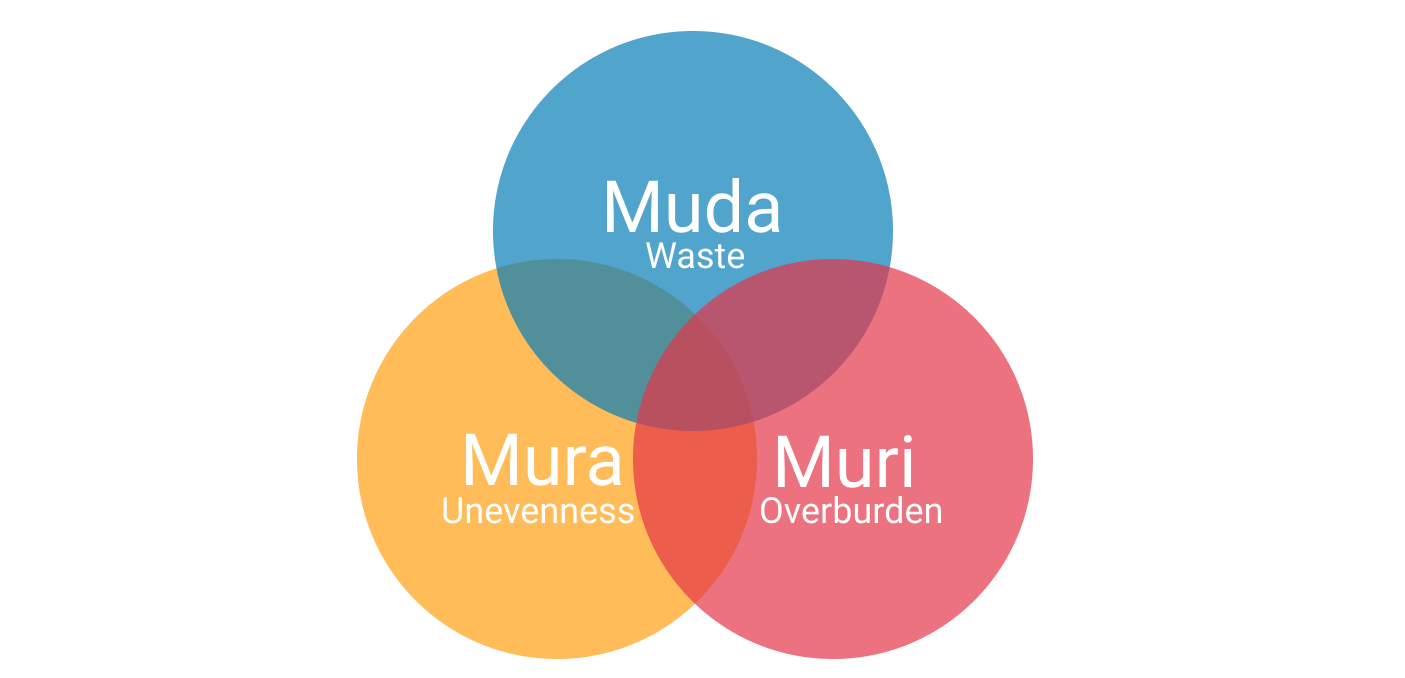

The Toyota 3M model: Muda, Mura, Muri Toyota has developed its production system around eliminating three enemies of Lean: Muda (waste), Muri (overburden) and Mura (unevenness) (Liker, 2004). Muda is the direct obstacle of flow.

Muda, Mura, and Muri The Three Wastes Kaizen News

Muda Muda refers to processes or activities that don't add value. These types of waste do not help your business or workers in any way. They increase costs and make tasks take much longer than they should. Wastes are defined in TPS as follows: • Overproduction occurs when items are manufactured before they are required.

What is the Difference between Muda, Mura and Muri? MadgeTech

So, let me now introduce the Mura, Muri, Muda. Mura. Eliminating unevenness or irregularities in any operation or process is one of the main principles of the Just-In-Time system, the main pillar of the Toyota Production System. I'm sure you've experienced times of unevenness, with high peaks, low valleys, and impacts labor productivity.

Muda, Mura, Muri (The Toyota 3M Model)

October 2, 2020 Take a closer look at the concepts of muda, mura, and muri and learn why you have to consider all three when you pursue any type of improvement or Kaizen actions. Hi everyone. This is Art Smalley, president of Art of Lean, Incorporated. Today, on behalf of the Lean Enterprise Institute, I have another improvement video for you.

Muda, Mura and Muri All you need to Know

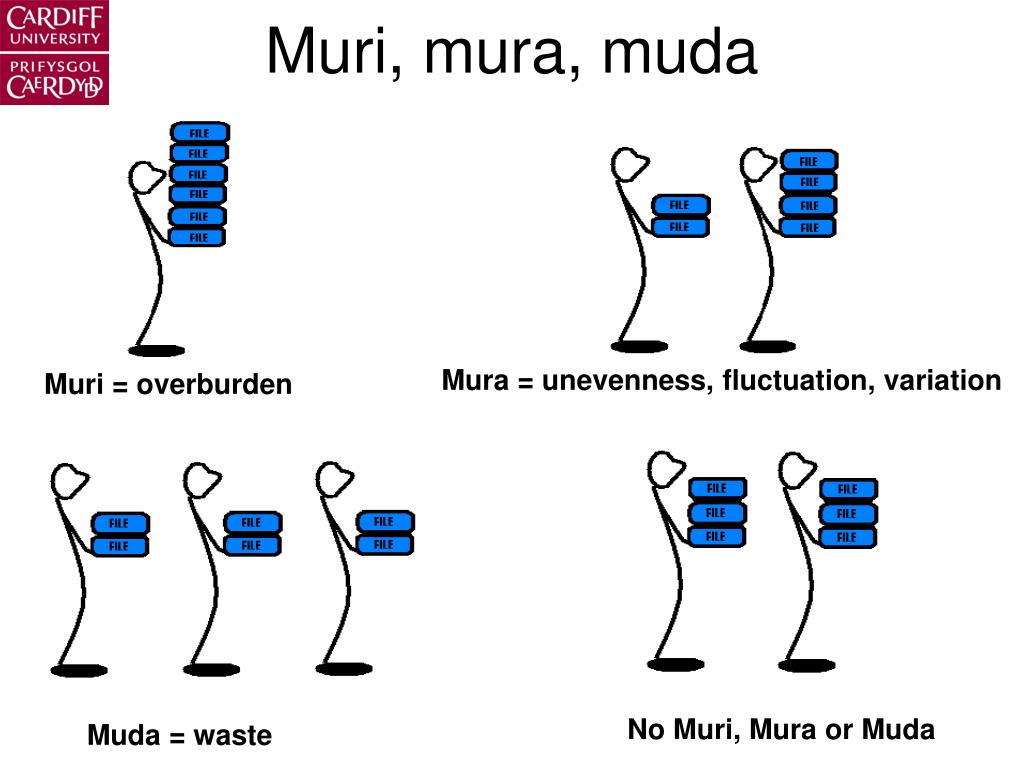

5S System Sort Shine Standardize Sustain Idea in short One of the most important goals of Lean manufacturing is the elimination of waste. Taiichi Ohno, father of the Toyota Production System (TPS), defined three categories of waste: Mura, Muri and Muda. While Muda is the most widely known, Muri and Mura are equally important to understand.

What is MURI, MURA, MUDA

Remove Muda, Mura and Muri. Lean Manufacturing is about the removal of waste; but not just Muda (non-value adding steps), it is about removing Mura and Muri too. In fact by concentrating on solving Mura and Muri you prevent the creation of Muda. By working on Just in Time (JIT) principles with Heijunka, Kanban and other techniques you enable production smoothing and flow; removing the causes.

Muda, Muri e Mura Saiba como identificar e reduzir desperdícios

Muri is the Japanese term for an excessive amount of workload placed on people, systems, or processes. It results from poor resource management, exaggerated hopes, and bad planning. Muri can have very negative effects, such as raising stress levels, lowering employee morale, increasing error rates, and lowering overall quality.

7 desperdicios, Mura, Muri, Muda Las 3 mu Lean Solutions

Muda refers to waste in the most basic sense: any activity that doesn't add value. There are seven wastes of manufacturing identified as muda, each one a common cause of loss during production. It includes: defects, waiting, motion, inventory, overproduction, over processing, and transportation.

Poster Muda Mura Muri

The terms muda, mura, and muri (waste, unevenness, and overburden) are actually not an invention by Toyota. They were used in Japanese martial arts long before Toyota. In martial arts, any excess movement in combat is a waste, since it tires the athlete and leaves him open for an attack. Similarly, any uneven or unnatural movement or thought.

Muda, Mura e Muri entenda definitivamente os 3Ms do sistema Toyota de

Muda, Mura, and Muri are concepts rooted in the Toyota Production System, also known as Lean Manufacturing. Developed by Toyota in the 1940s, this system revolutionized the manufacturing industry by emphasizing the elimination of waste to achieve operational excellence. The Three Ms serve as a guide for identifying different types of waste and.

PPT Waste and failure demand PowerPoint Presentation, free download

Looking at it collectively When examining business processes for inefficiencies, it is important to take into consideration the presence of all three - Muda, Mura, and Muri. They are all interrelated and are all considered wastes. One does not look for Muda alone and hope to solve a process problem completely.

Muda, Mura, and Muri The Three Wastes Kaizen News

Motion: Unnecessary physical movement of people or equipment. Waiting: Idle time or delays in the workflow. Overproduction: Producing more than what is demanded by the customer. Over processing: Adding more value than necessary to a product or service. Defects: Errors or mistakes that require rework or correction.

Kaizen Muda Mura Muri Template for PowerPoint SlideModel

We had made an intense effort that summer to understand these new Japanese terms for waste (muda), unevenness in operations (mura), and overburdening of people and equipment (muri) that entered our lives when John Krafcik joined our team from NUMMI, the Toyota/GM joint venture in California.

Lean manufacturing Muda, Mura và Muri

Muda, Muri, Mura Genba. Eliminating waste is the key to efficiency - in the Toyota Production System, this is termed as Muda, Muri and Mura. Read on to see our explanation. Muda means waste and refers in management terms to a wide range of non-value-adding activities. Eliminating waste is one of the main principles of the Just-in-time system.

Finding Mura (variation) in your Process MudaMasters

Muda This is the best-known of the three areas of waste. It contains the seven classic wastes as defined by Ohno. They are: Transportation - The inefficient movement of products and supplies from one place to another. Inventory - The storing of too many or too few products or supplies.